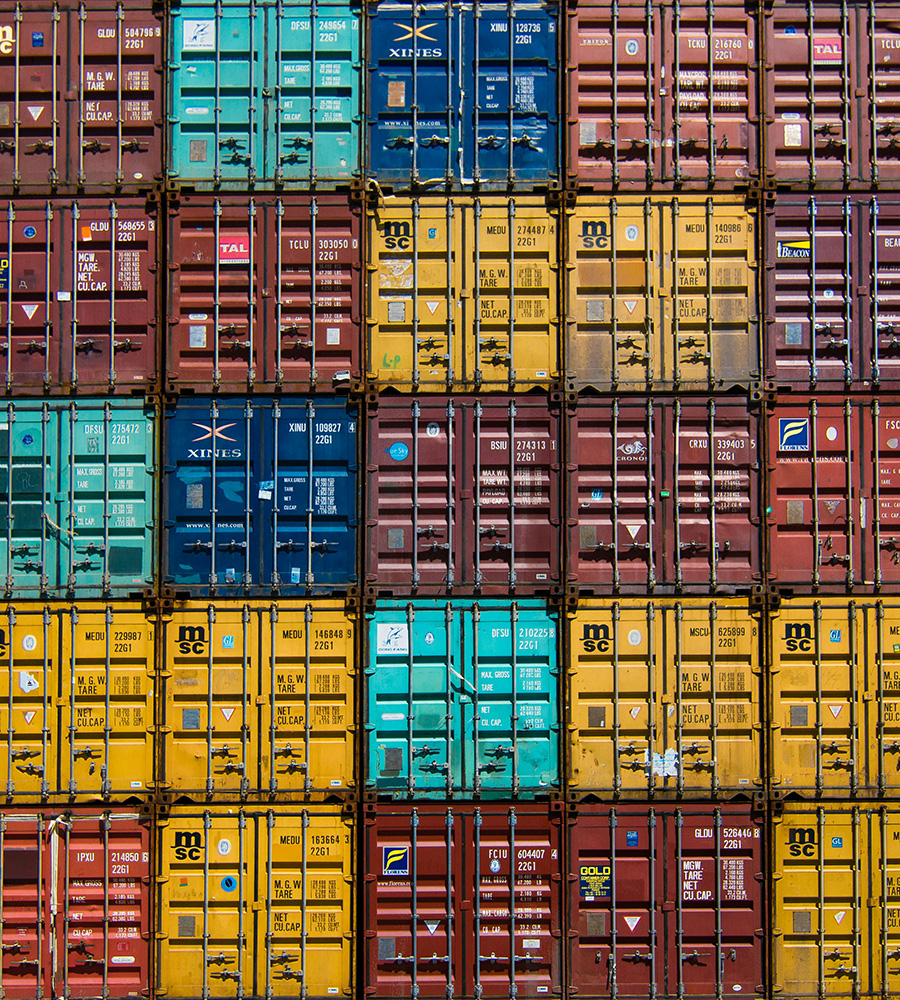

You’ve probably seen “deadstock” mentioned in fashion or design circles. It sounds mysterious, maybe negative. Actually, it’s just unsold fabric sitting in warehouses – high-quality materials that didn’t get used for their original purpose. Understanding what deadstock really means helps you see why small brands and independent designers seek it out.

What deadstock fabric actually means

Deadstock is leftover fabric. A mill produces 5,000 yards for a major brand. The brand only uses 4,200 yards. The remaining 800 yards sit in storage. That’s deadstock.

Or a retailer orders fabric for a collection that gets cancelled. Or a manufacturer over-produces. Or archive fabrics from years ago that ever sold. None of this is defective material. It’s just excess inventory that didn’t fulfill its original commercial purpose.

People confuse deadstock with seconds or damaged goods. Not the same thing. Deadstock is first-quality fabric that simply became surplus. It’s also not secondhand or reclaimed from used clothing. It’s unused, often still on the original bolt.

The term gets murky because suppliers use “deadstock” loosely. Some mean genuine mill overruns. Others mean old inventory they’re clearing. Knowing the actual source helps you understand what you’re getting – fresh overrun versus fabric that’s been sitting for a decade.

Why does deadstock exist at all? Production planning isn’t perfect. Brands overestimate needs to avoid shortages. Mills produce extra to account for defects. Retailers cancel orders mid-production. Fashion seasons change and inventory becomes obsolete. All these create surplus.

The fabric itself is usually identical to what went into finished products. Same mill, same quality standards, same production run. The only difference is it didn’t get used by the original client. This matters because you’re not getting inferior material – you’re getting the same thing that could’ve ended up in a high-end garment or interior project.

Why designers choose dead stock fabric for real projects

Small production runs make deadstock appealing. You’re making 50 pieces, not 5,000. Ordering custom fabric from a mill requires minimum quantities you can’t hit. Dead stock fabric lets you get interesting materials in smaller quantities that actually match your scale.

The fabrics themselves are often unusual. Mills produce specialty weaves, unique prints, or experimental blends for big clients. Those clients use most of it, but the leftovers become available. You end up with access to materials that would normally be locked into major brand contracts or would require massive minimum orders.

Quality control is simpler. The fabric already exists. You can see it, touch it, and test it before committing. No waiting for mill samples or production runs that might not match what you expected. What you see is literally what you get.

I used deadstock Italian wool for a small jacket run last year. Needed 40 yards. Beautiful herringbone, perfect weight. Ordering that same quality custom would’ve required a 200-yard minimum plus weeks of sampling. Deadstock meant I got exactly what the project needed without excess or delays.

Costume designers use deadstock constantly. Theater, film, and editorial shoots – they need specific looks in limited quantities. One period dress, one statement piece for a photoshoot. Deadstock gives them unique fabrics without ordering massive bolts they’ll never use again.

Small interior projects work similarly. Custom cushions for a boutique hotel lobby. Accent chairs for a showroom. You need 10 yards of something special, not a full production run.

How deadstock fabric is used in fashion and interiors

Fashion designers build entire capsule collections around deadstock finds. Five dresses in one fabric, ten shirts in another. The limited quantity actually becomes part of the appeal – genuinely limited editions because the fabric can’t be reordered.

I’ve seen designers create whole seasonal collections by selecting 4-5 deadstock pieces and designing around what’s available. Constraints force creativity. You can’t just order more if something sells out, so you design accordingly.

Ready-to-wear brands use deadstock for special releases. Main collection uses their standard fabrics, but a small drop uses deadstock for something different. Lower financial risk, tests new ideas, creates variety.

Interior designers use deadstock for accent pieces that need visual interest without a big investment. Custom cushions in unique fabrics. Upholstered headboards. Window treatments for small spaces. Anywhere you want something special but don’t need yards and yards.

Photography and styling projects eat up deadstock. Magazine shoots need specific looks for one day. Set designers need particular fabrics for backgrounds or props. Film costumes need authenticity that modern mass-produced fabrics don’t have. Deadstock archives often contain older weaves and finishes that aren’t manufactured anymore.

The visual unpredictability works for creative projects. You’re not working from a predictable catalog. You’re responding to what exists, which can push you in unexpected directions.

Things to know before working with deadstock fabric

Limited yardage means limited options. That gorgeous silk might only have 15 yards available. If your project needs 20, you’re stuck. Always confirm quantity before designing.

You can’t reorder. Make a successful piece, and customers want more? Can’t happen unless you find similar fabric elsewhere. This affects how you plan collections and manage expectations. Some brands embrace this. Others find it restrictive.

Fabric condition varies. Most deadstock is pristine. Some have sat in warehouses for years – slight discoloration, mustiness, stiffness from storage. Request samples if buying remotely. Check for fading, water marks, storage damage.

Composition and weight matter more because you can’t customize. Regular production lets you specify exactly what you need. Deadstock is what it is. A beautiful print in the wrong weight doesn’t help. Know your requirements before committing.

Drape and hand feel need testing. Photos don’t show how fabric moves or feels. Crucial for garments, less so for interiors, but always worth checking. Get swatches, test them, see if they work for your application.

Storage becomes your responsibility. Buy 50 yards for a project needing 30, you’re storing 20 yards indefinitely. Some designers buy exactly what they need. Others buy available stock and design around it later.

Deadstock isn’t a sustainability trend. It’s a practical sourcing option for specific scales and approaches. Understanding the constraints helps you decide when it makes sense.