Rosin is made by applying heat and pressure to cannabis flower or hash to extract its natural oils. The process does not use any solvents or chemicals, relying purely on heat and mechanical force to separate the resin from the plant material. This method preserves the full spectrum of cannabinoids and terpenes, resulting in a clean, flavorful concentrate.

The extraction begins by placing the cannabis material between heated plates and pressing it until the oils are released. Temperature and pressure are carefully controlled to maximize yield while maintaining quality. The collected rosin is then cooled and stored, ready for consumption or further use in concentrates and infused products.

The Full Rosin Process: Step-by-Step

Making rosin follows a clear and organized process to ensure the final product is of high quality.

1. Preparing the Material

The cannabis is packed into nylon mesh filter bags. Food-grade nylon is generally used for its heat-resistant and food-safe properties. These bags act as strainers, letting melted resin out while holding plant material in. The cleaner the material (like hash), the finer the mesh used. The material is then shaped into a tight, even “puck.” This helps heat and pressure spread evenly during the pressing process.

2. The Press Cycle

The puck is wrapped in parchment paper and placed between heated plates. The plates gently close, allowing the material to warm up evenly. Then pressure is slowly increased—usually over 30 to 60 seconds—until it reaches the target PSI. The rosin flows out of the bag and spreads onto the paper. The press is held for anywhere from 30 seconds to 3 minutes until the resin stops flowing.

3. Cooling and Collecting

As soon as pressing ends, the parchment paper is placed on a cold surface. This stops the heat from damaging the fresh rosin. Once cooled, the rosin is scraped up using a stainless steel tool. Many extractors then cure the rosin by whipping it or lightly heating it to create smoother textures, such as badder, jam, or cold cure.

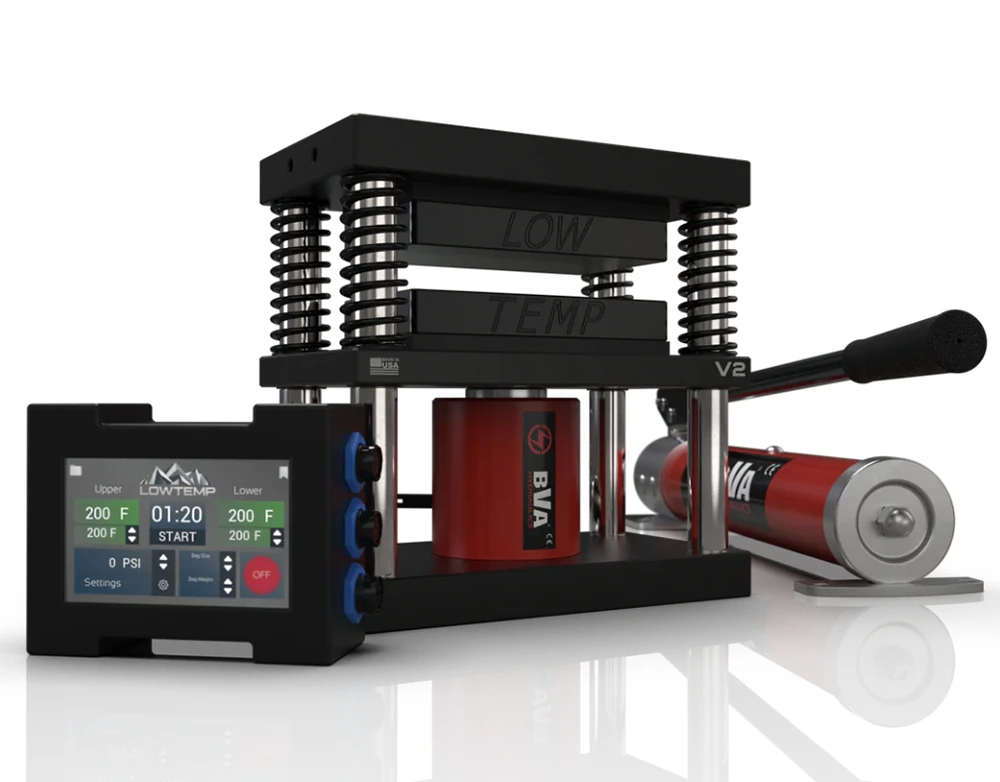

The Rosin Press: How It Works

A rosin press is the machine responsible for making rosin. It uses two heated metal plates that squeeze cannabis material until the resin inside melts and flows out.

Rosin presses seem simple, but high-quality models are built for accuracy and consistency. Without the right temperature and pressure control, the extract won’t turn out correctly.

Commercial rosin makers rely on advanced presses. The top-quality rosin presses by Lowtemp Industries are designed to maintain even heat, apply steady pressure, and withstand constant use.

One of Lowtemp Industries’ most advanced setups, the V2 Medusa System, connects five presses, allowing them to run together. This dramatically increases output while still allowing each press to be independently controlled. This type of setup is ideal for large operations where consistency is crucial.

The Starting Material: The Biggest Factor in Quality

The cannabis you start with is the biggest factor in how good your rosin will be. Better material equals better rosin—there’s no way around it.

Rosin usually comes from one of three sources:

Flower Rosin

Pressed from dried cannabis flower. Suitable for beginners, but the final product may contain more plant wax since the entire flower is used.

Kief/Sift Rosin

Made from collected trichomes (the tiny, crystal-like resin glands). Cleaner than flower rosin and usually produces more oil.

Hash Rosin

Made from bubble hash, often produced using fresh-frozen cannabis. This is considered the gold standard because it preserves the best flavor, strongest terpene profile, and highest purity.

Heat: How Temperature Shapes the Final Product

Temperature has a significant impact on the quality of rosin, as its texture, flavor, and aroma all change depending on the temperature of the plates.

- Lower temperatures (160°F–190°F) are used when flavor and terpene preservation are the main goals. This is common with hash rosin. The result is lighter, creamier rosin with more smell and taste.

- Higher temperatures (200°F–220°F) are used more often with flowers because it takes more heat to release the resin. This can increase yields but may lower terpene levels, causing the rosin to look darker and taste slightly more “cooked.”

Pressure Explained: What PSI Means

“PSI” stands for pounds per square inch. It’s a measurement of how much force is being applied to every inch of the material being pressed.

Here’s an easy way to picture it:

- Imagine someone stepping on your foot with a flat shoe.

- Now imagine that same person stepping on your foot with a high heel.

The person weighs the same, but the pressure is completely different.

The heel applies more PSI because all that weight is concentrated on a much smaller area.

In rosin pressing, PSI tells you how much squeezing force is being applied to your cannabis inside the press. Too much PSI will crush the plant material and contaminate the rosin. Too little PSI might not release enough resin.

General PSI ranges

- Hash/kief: Gentle pressure, about 300–700 PSI

- Flower: Stronger pressure, about 600–1,000 PSI

Using the right PSI helps prevent issues like blowouts, which occur when the filter bag bursts under excessive pressure, mixing plant material into the rosin.

Why Rosin Is Leading the Future of Clean Cannabis

Rosin continues to gain popularity because consumers want safer, cleaner, and more flavorful concentrates. Since it uses no chemicals and stays true to the plant, it naturally meets these expectations.

The future of rosin production relies on three key principles:

- Precision equipment: High-quality presses enable the production of consistent, top-tier rosin in larger batches.

- Smart temperature and pressure control: Understanding how heat and PSI impact the material is essential for flavorful, stable concentrates.

- Pure starting material: Using high-quality flower, hash, or kief ensures clean, aromatic rosin, with live rosin from fresh-frozen cannabis representing the pinnacle of purity.

At its heart, rosin making is about respecting the plant. By relying solely on heat and pressure, extractors preserve the natural chemistry of the cannabis in its purest form, making rosin the gold standard of solventless concentrates.